- Home

- Products

- About us

- Download Center

- News

- Stock

- Contact

Product Description

Product Description

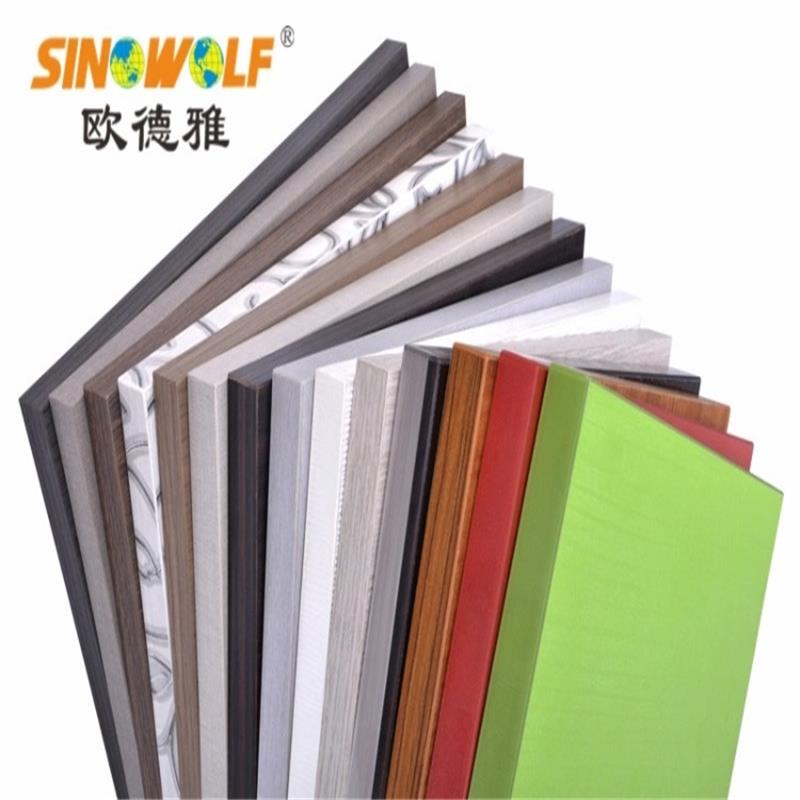

Formica Edge Tape by SINOWOLF is a premium furniture finishing material designed to provide both protection and aesthetic enhancement for cabinets, countertops, and other laminated furniture surfaces. Manufactured in Dongguan, China, this edge tape ensures a professional finish, strong durability, and resistance to everyday wear and tear. With a daily productivity of 1,000,000 meters, we can guarantee a stable supply for bulk and recurring orders. All products meet ISO, SGS, ITS, and BVHS certifications, ensuring international quality standards.

Brand: SINOWOLF

Usage: Specially designed for cabinet and furniture edge finishing

Condition: 100% New, high-quality production

Sample: Free samples available for testing before bulk order

Standard: Matches customers’ raw standards for seamless application

Certificate: ISO / SGS / ITS / BVHS certified for quality and safety

HS Code: 3616209000

Productivity: Up to 1,000,000 meters per day, ensuring high-volume supply

Packaging: Cartons and palletized for safe transport

Transportation: Available by ocean, land, or air to meet global logistics needs

Place of Origin: Dongguan, China (mainland)

| Model No.: | F01 |

| Brand: | SINOWOLF |

| Usage: | Cabinet |

| Condition: | New |

| Sample: | Free Sample For Test |

| Standard: | Match To Customer's Raw Standard |

| Certificate: | ISO/ SGS/ ITS/ BVHS |

| Code: | 3616209000 |

| Productivity: | 1,000,000m/day |

| Packaging: | Cartons,Pallet |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | Dongguan,CHINA(mainland) |

✅ High Productivity: Large-scale production ensures stable supply capacity.

✅ Certified Quality: International certifications (ISO/SGS/ITS/BVHS) guarantee reliability.

✅ Customizable: Can be tailored to customer standards for perfect material matching.

✅ Durability: Provides long-lasting protection against impact, scratches, and moisture.

✅ Professional Finish: Delivers a seamless look that enhances furniture aesthetics.

✅ Convenient Logistics: Flexible transport options for global customers.

✅ Free Samples: Risk-free testing before placing orders.

Cabinetry: Kitchen cabinets, bathroom vanities, and wardrobes.

Office Furniture: Desks, partitions, and storage units.

Commercial Use: Retail displays, counters, and shelving.

DIY and Custom Projects: Tailored furniture requiring high-quality edge finishing.

Laminated Surfaces: Provides protection and decorative edges for various furniture types.

Ensure the surface is clean, dry, and dust-free before applying the tape.

Follow recommended temperature and pressure settings when using edge banding machines.

Avoid direct exposure to open flames or extreme heat.

Store in a cool, dry place, away from moisture and direct sunlight.

Handle packaging carefully to prevent deformation before use.

Q1: Can I get a sample before placing an order?

Yes, we provide free samples for testing to ensure quality meets your requirements.

Q2: What certifications does SINOWOLF Formica Edge Tape have?

Our products are certified by ISO, SGS, ITS, and BVHS, meeting international standards.

Q3: What is your daily production capacity?

We can produce up to 1,000,000 meters per day, supporting bulk and long-term orders.

Q4: How do you package the edge tape for delivery?

All products are packed in cartons and pallets to ensure safe transport.

Q5: Can Formica Edge Tape be customized?

Yes, it can be customized to match customers’ raw standards, including color, texture, and size.

Q6: Where is the product manufactured?

Our Formica Edge Tape is produced in Dongguan, China (mainland).