Edge banding is a processing technology commonly used in the wood-based panel industry, mainly to solve the problem of edge exposure of wood-based panels. This technology can also be used for decorative effects. The edge banding series of products are mainly divided into two types: hot-melt type and water-based type.

The hot-melt type uses a hot-melt adhesive as the bonding material, which is melted and applied to the edge of the panel by a hot-melt machine, and then cooled and solidified to achievethe bonding effect. The water-based type uses a water-based adhesive as the bonding material, which is applied to the edge of the panel by a glue gun or brush, and then dried to achieve the bonding effect. The edge banding series of products have good bonding strength, water resistance, wear resistance and other properties, and can be used for various wood-based panel edges.

| Product Attributes |

| Model No. | PR-01 | Brand | SINOWOLF |

| Material | PVC | Usage | Sofa |

| Condition | New | Sample | Free Sample For Test |

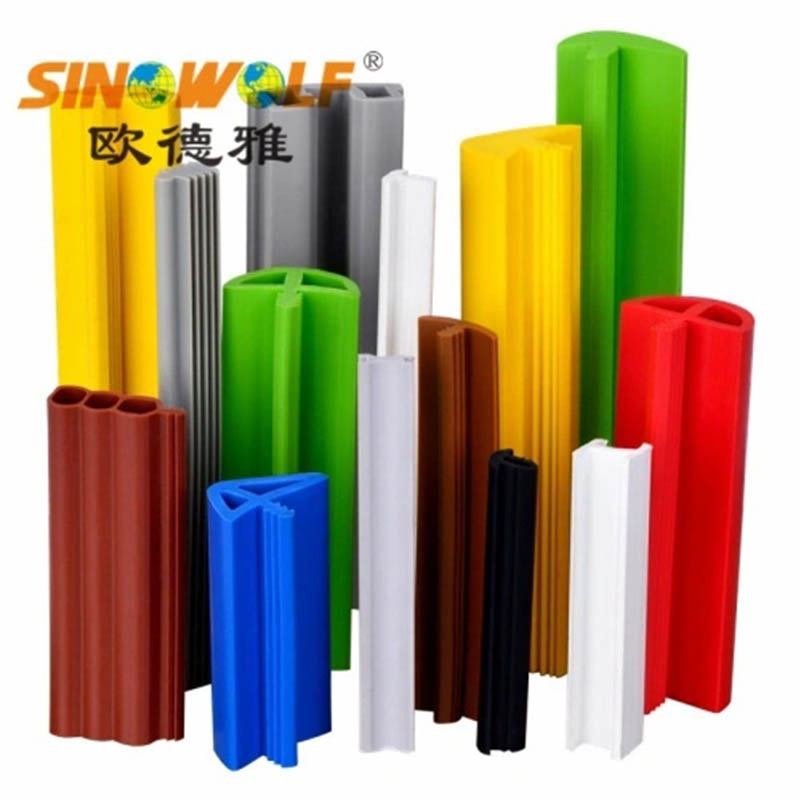

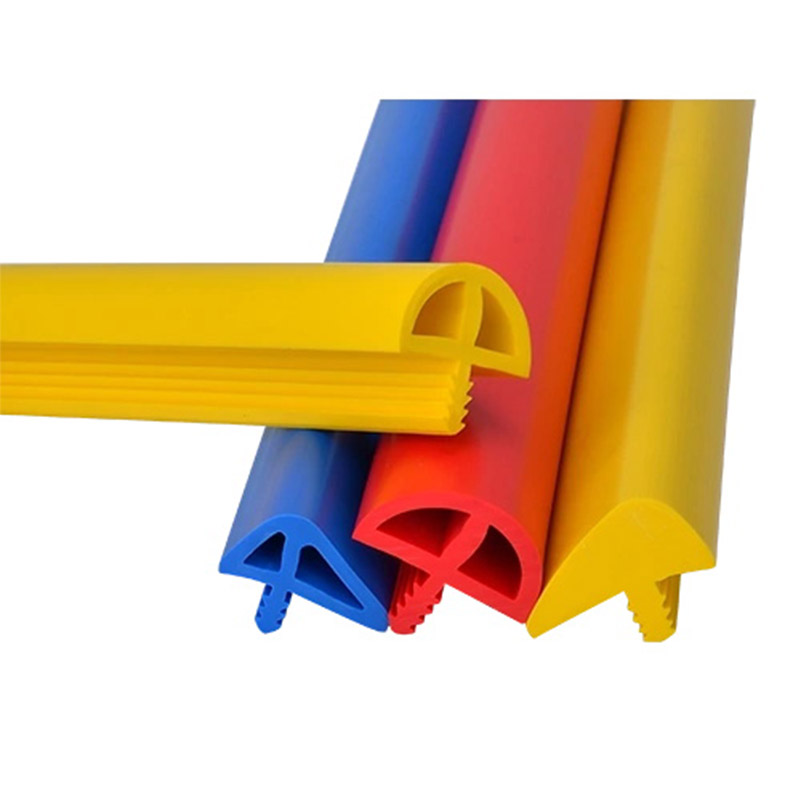

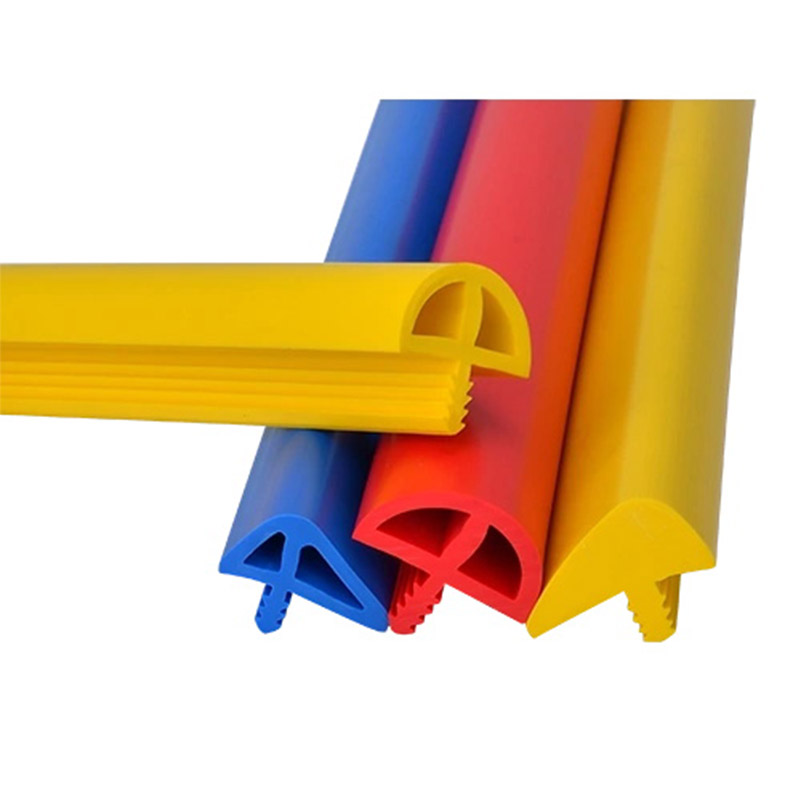

| Shape | All Kinds Of Shape As Customize | HARDNESS | Sof And Hardness Can Be Adjust |

| Supply Ability & Additional Information |

| Packaging | carton,pallet | Productivity | 10000m/day |

| Transportation | Ocean,Land,Air | Place of Origin | Dongguan,CHINA(mainland) |

| Supply Ability | 10,000 meter/day | Certificate | ISO/ SGS/ ITS/ BV |

| HS Code | 3916909000 | Payment Type | L/C,T/T |

| Incoterm | FOB,CFR |

|

|

| Packaging & Delivery |

| Selling Units | Meter |

| Package Type | carton,pallet |

High wear resistance: Profile Edge Banding Series has high wear resistance, which can effectively prevent wear and tear during use.

Good water resistance: Profile Edge Banding Series has good water resistance, which can effectively prevent water damage during use.

Corrosion resistance: Profile Edge Banding Series has good corrosion resistance, which can effectively prevent corrosion during use.

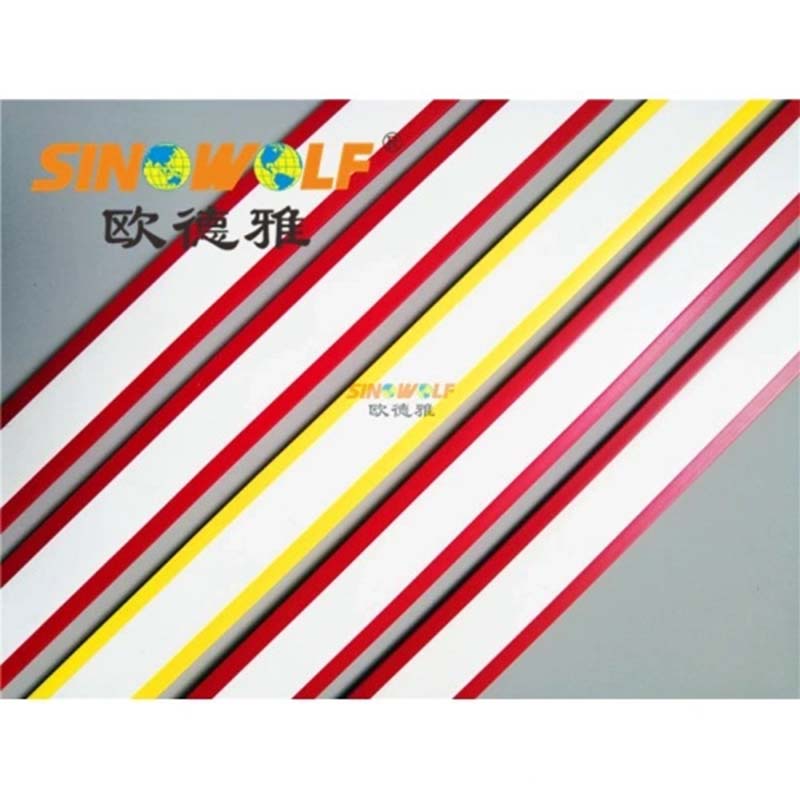

High decorative effect: Profile Edge Banding Series can provide a high decorative effect, making the overall appearance more fashionable and upscale.

Easy to use: Profile Edge Banding Series is easy to use, simple to install, and convenient to maintain.

Long service life: Profile Edge Banding Series has a long service life, which can greatly extend the service life of wooden crafts.

Cost-effective: Profile Edge Banding Series has a cost-effective performance, which can save costs for users.

Wide range of uses: Profile Edge Banding Series is widely used in furniture, flooring, doors and other wooden crafts, and is especially suitable for high-end wooden crafts or occasions that require high quality.

Advantages of our company's products - Profile Edge Banding Strip:

1.Customize PVC profile edge banding.

2.Imported PVC material.

3.Customize the hardness according requests.

4.Various designs and molds for choose.

5.Stable color and quality between different lots.

What is edge banding?

Edge banding is a woodworking process that involves applying a strip of material to the edge of a board or panel to hide the unsightly cut edge, enhance appearance, and add structural strength. It is commonly used in the furniture, flooring, and cabinetry industries.

What are the different types of edge banding?

There are two main types of edge banding: hot-melt and water-based. Hot-melt edge banding uses a hot-melt adhesive to bond the banding material to the panel edge, while water-based edge banding uses a water-based adhesive.

What is the process of applying edge banding?

The process of applying edge banding involves cleaning the panel edge, measuring and cutting the banding material to the correct length, melting the hot-melt adhesive or mixing the water-based adhesive, applying the adhesive to the panel edge, and then pressing the banding material onto the adhesive.

What are the benefits of using edge banding?

Edge banding offers several benefits, including improving the appearance of the panel edges, adding structural strength, and protecting the edges from damage or chipping. It can also be used to create a consistent look when joining multiple panels together.

What are some common uses for edge banding?

Edge banding is commonly used in furniture manufacturing, flooring installation, and cabinet production. It is also commonly used in DIY projects and home improvement projects to improve the appearance and durability of woodworking projects.