In modern furniture manufacturing, the finish of furniture components is as important as the design itself. The edges of panels, countertops, and cabinet doors are often the first point of contact, both visually and physically. This makes edge banding an essential component for durability, aesthetics, and functionality. Among the various materials available, PVC Edge Banding stands out as a versatile, durable, and cost-effective solution. For furniture designers and manufacturers looking to create unique furniture parts and designs, custom PVC edge banding solutions are increasingly becoming the standard.

What Is PVC Edge Banding?

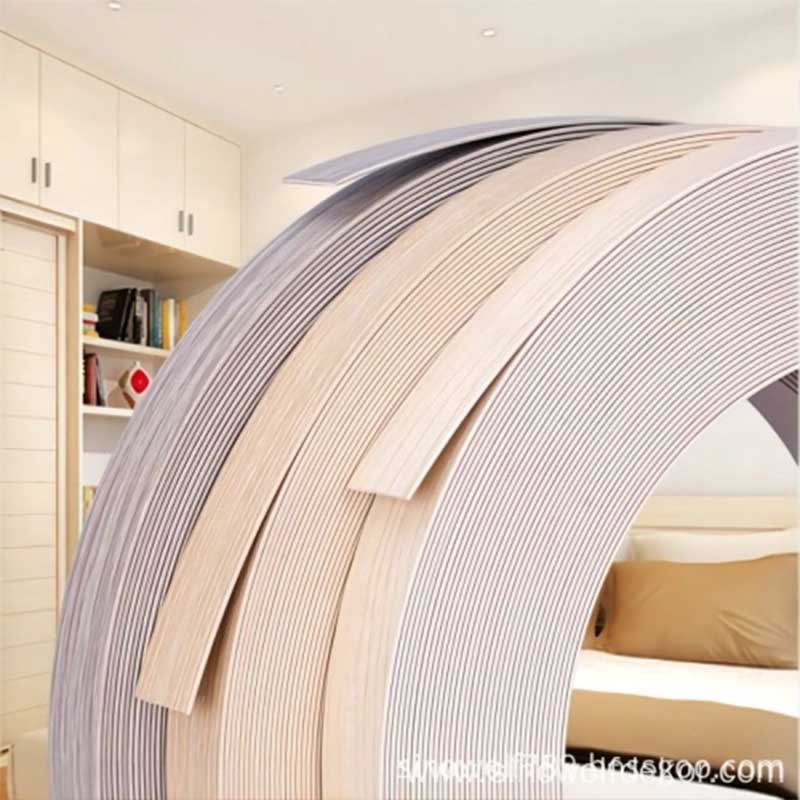

PVC (Polyvinyl Chloride) edge banding is a thin strip of thermoplastic used to cover the exposed edges of furniture panels. It is widely used in furniture parts such as MDF, particle board, plywood, and other engineered wood products. The primary functions of PVC edge banding include:

Protecting panel edges from moisture, scratches, and impact.

Improving the aesthetic appearance by providing a smooth, finished look.

Extending the longevity of furniture components.

Offering customizable options in terms of colors, patterns, and textures.

PVC edge banding is favored for its flexibility, affordability, and ease of processing. It can be heat-bonded or glued to panels, making it suitable for a wide range of furniture styles and custom designs.

Why Custom PVC Edge Banding Is Essential for Unique Furniture Parts

Standard edge banding comes in common colors and patterns, which may not match specialized or premium furniture designs. For custom furniture projects, whether it’s high-end cabinets, designer desks, or bespoke wardrobes, custom PVC edge banding ensures:

Perfect Color Matching – Custom colors allow designers to match the banding exactly with panel surfaces, creating a seamless, professional look.

Unique Patterns and Textures – Grain patterns, wood textures, and metallic finishes can be reproduced to meet specific design visions.

Special Sizes and Thicknesses – Standard banding may not fit uniquely shaped or thick panels; custom solutions accommodate unusual dimensions.

Enhanced Durability – High-quality PVC formulations can be customized for wear resistance, heat resistance, and anti-scratch properties, which is critical for frequently used furniture parts.

With custom solutions, designers and manufacturers can differentiate their products in a crowded market, offering furniture that stands out for both form and function.

Applications of Custom PVC Edge Banding

PVC edge banding is used across various furniture parts and designs:

Cabinet Doors and Drawer Fronts

Custom PVC banding protects edges that undergo frequent opening and closing, preventing chipping and water damage.Tabletops and Work Surfaces

Edge protection is essential for dining tables, office desks, and kitchen counters. Custom banding can mimic premium wood or metallic finishes.Shelving and Bookcases

Exposed edges can be reinforced while maintaining aesthetic consistency with the furniture’s overall design.Wardrobes and Storage Units

Custom PVC banding provides long-lasting protection for high-use panels and ensures color and texture continuity across large surfaces.Specialty Furniture

Designer pieces with unique shapes, curves, or inlays require tailored banding solutions for seamless finishing.

Advantages of Custom PVC Edge Banding for Furniture Design

Enhanced Aesthetics

Custom PVC edge banding allows designers to create cohesive, visually appealing furniture, matching colors, patterns, and textures perfectly. This creates a high-end, luxurious look even on budget-friendly panels.Increased Durability

Furniture edges are vulnerable to chipping, moisture infiltration, and daily wear. PVC edge banding offers long-term protection, significantly extending the lifespan of furniture components.Versatility and Flexibility

PVC can be applied to straight or curved edges, enabling innovative furniture designs without compromising structural integrity.Cost-Effective Customization

Compared to solid wood edging or other premium materials, PVC edge banding is affordable, lightweight, and easy to install, making it suitable for both mass production and custom projects.Environmental Resistance

PVC is resistant to water, heat, and many chemicals, ensuring furniture maintains its appearance and strength over time, even in kitchens, bathrooms, and offices.

Choosing the Right PVC Edge Banding for Your Project

Selecting the proper PVC edge banding involves several considerations:

1. Thickness and Width

Edge banding typically ranges from 0.4mm to 3mm in thickness and widths from 10mm to 60mm or more. Custom furniture parts with unique panel thicknesses require tailored sizing for a seamless fit.

2. Color and Pattern

Custom PVC solutions allow exact color matching to laminate surfaces, veneers, or painted panels. Popular patterns include wood grain, stone textures, metallic finishes, and solid colors.

3. Adhesive Type

PVC edge banding can be applied using pre-applied hot-melt glue or separate adhesives. Hot-melt adhesive simplifies production for high-volume manufacturing, while separate gluing provides flexibility for intricate shapes.

4. Edge Profile

Standard flat edges are common, but custom furniture may feature rounded, beveled, or chamfered edges. Custom PVC banding can accommodate these profiles for precise finishing.

5. Special Features

Additional properties like UV resistance, anti-scratch coating, or fire retardancy can be incorporated into custom PVC formulas for furniture intended for commercial or outdoor use.

Custom PVC Edge Banding in Modern Furniture Design Trends

With the rise of modern, minimalistic, and multifunctional furniture, edge banding is no longer just functional—it’s a design element. Popular trends include:

Matte and Satin Finishes – Smooth, elegant surfaces that complement contemporary cabinetry.

Metallic and Glossy Edges – High-end look for luxury desks and tables.

Contrasting Colors – Banding in bold colors to create visual interest on neutral panels.

Wood Grain Replication – Provides the look of exotic woods without the high cost or maintenance.

These trends highlight why custom PVC edge banding is essential for creating unique furniture parts and designs that resonate with consumers and clients.

Installation Tips for Custom PVC Edge Banding

Prepare the Panel Surface – Ensure edges are clean, smooth, and free from dust.

Apply Adhesive – Pre-glued banding can be heat-activated using an edge banding machine or iron.

Trim Excess Banding – Use a precise trimmer to remove overhang.

Finish and Sand Edges – Light sanding creates a seamless, professional look.

Inspect for Quality – Check adhesion, color matching, and alignment for perfection.

Proper installation ensures the edge banding not only enhances aesthetics but also performs its protective function effectively.

Benefits for Manufacturers and Designers

Customization Capabilities – Tailor edge banding to specific projects, providing differentiation in competitive markets.

Time and Cost Efficiency – PVC is easy to handle and reduces waste compared to solid wood edging.

High Customer Satisfaction – Finished furniture looks premium and maintains durability, which increases client trust and repeat business.

For designers creating miniature or full-size furniture parts, integrating custom PVC edge banding allows maximum flexibility in design and finish.

Case Study: Applying Custom PVC Edge Banding to Unique Furniture Parts

Consider a designer building a modular office desk system. Panels vary in thickness from 18mm to 28mm, and each requires edge banding that matches laminate color perfectly. Standard off-the-shelf edge banding could not cover this variation. By using custom PVC edge banding:

Each panel received a perfectly matched color finish.

The durable PVC protected the high-contact edges from chipping.

Curved corner panels were banded seamlessly with no gaps.

The final product achieved a high-end look, durability, and consistency across all parts, demonstrating the critical role of custom PVC edge banding.

Conclusion

For modern furniture manufacturers, interior designers, and DIY enthusiasts, custom PVC edge banding is no longer optional—it’s essential. It enhances aesthetics, provides durability, and supports innovative design, enabling the creation of unique furniture parts and designs.

From protecting edges to adding style elements, PVC edge banding bridges the gap between functionality and beauty. Whether you are designing cabinets, tables, wardrobes, or custom projects, investing in tailored solutions ensures your furniture stands out, lasts longer, and meets professional quality standards.

For any project, whether industrial-scale or bespoke miniature furniture, custom PVC edge banding solutions deliver the flexibility, protection, and elegance required for contemporary designs.