In the modern home design and construction industry, the selection of materials plays a decisive role in the quality, durability and aesthetics of products. Polypropylene Edge Banding Tape (Acrylic Edge Banding Tape) as a widely used in furniture and building materials edge protection material, its unique properties and many advantages make it become the industry's preferred material. This paper will deeply discuss the material characteristics and advantages of this kind of sealing tape, in order to provide valuable reference for designers and manufacturers.

Polypropylene edge sealing strips are mainly made of highly transparent polypropylene materials. This thermoplastic polymer is favored for its excellent chemical stability, weather resistance and ease of processing. Its transparent characteristics make the edge of the product can present a seamless beauty, which is particularly important for the pursuit of high-end visual effects of the design.

In terms of physical properties, the polypropylene edge sealing strip has excellent impact resistance. This means that it retains its original shape and function even when subjected to impact or pressure, effectively protecting the edges of the encapsulated object from damage. In addition, the hardness of the material is moderate, which provides strong protection while ensuring that no excessive wear is caused to the equipment during processing.

Temperature resistance is one of the key indexes to evaluate the quality of sealing tape materials. In this regard, polypropylene edge sealing tape also performs well. It can remain stable in the temperature range of -40 ° C to 90 ° C, which makes it suitable for a variety of indoor and outdoor environments, whether it is the cold northern region or the hot equatorial zone, to maintain its performance.

In addition to the above physical and chemical properties, polypropylene edge sealing tape also has excellent environmental characteristics. Because its material can be recycled and reused, it greatly reduces the environmental burden in the production process, and also meets the requirements of today's society for sustainable development.

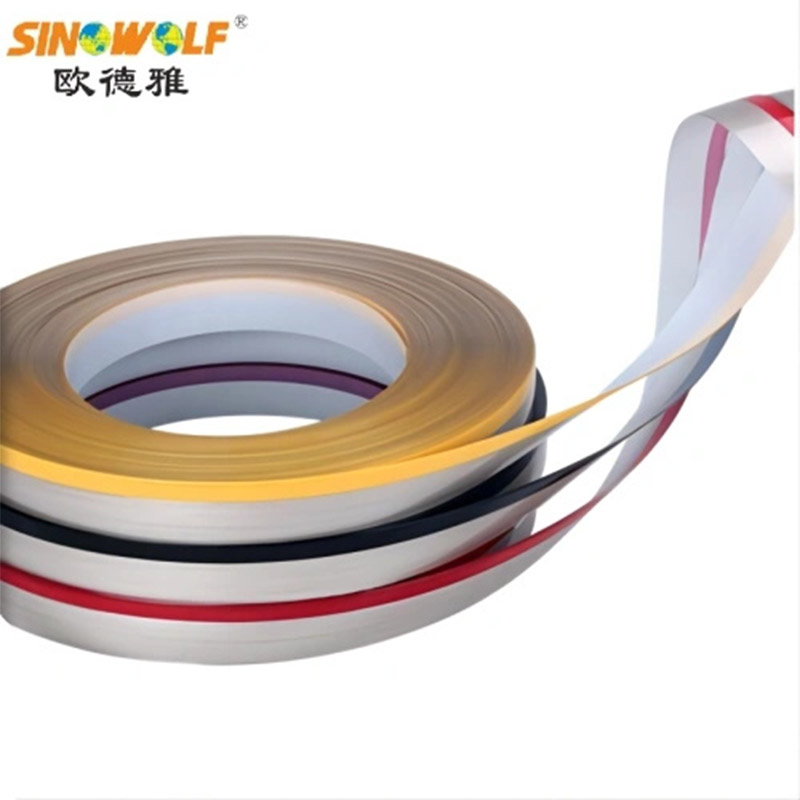

In practical applications, polypropylene edge sealing tape has shown many advantages. For example, when it comes to furniture edging, it can be perfectly combined with various types of boards, whether it is solid wood, particleboard or MDF, which can effectively prevent the intrusion of moisture and pollutants and extend the service life of furniture. At the same time, its rich color choices and customizable size range also provide more flexibility in the design.

In the construction industry, especially in outdoor applications, the high weather resistance of polypropylene edge sealing strips means that they do not fade, deform or embrittlement even under long-term exposure to sunlight and rain. This is essential to ensure the lasting aesthetic appearance of the building.

Compared with other common edge sealing materials such as PVC or rubber, polypropylene edge sealing has obvious advantages in weather resistance, environmental protection and transparency. While in some cases these materials may be chosen because of their lower cost, in the long run polypropylene offers superior overall performance, especially where long-term durability and high quality performance are required.

In summary, polypropylene edge sealing strips have become an integral part of the furniture and construction industry with their excellent physical properties, temperature resistance, environmental protection properties and diversified advantages in practical applications. It not only enhances the beauty of the product, but also ensures the durability and practicality of the product, which is a detail that cannot be ignored in modern design.

In the future, with the development of science and technology and the progress of material technology, the performance of polypropylene edge sealing strip will be further optimized, and its application in industrial design will be more extensive. For those manufacturers and designers who pursue excellent quality and innovative design, a deep understanding and reasonable use of this material will undoubtedly occupy a place in the fierce market competition