Early Beginnings:

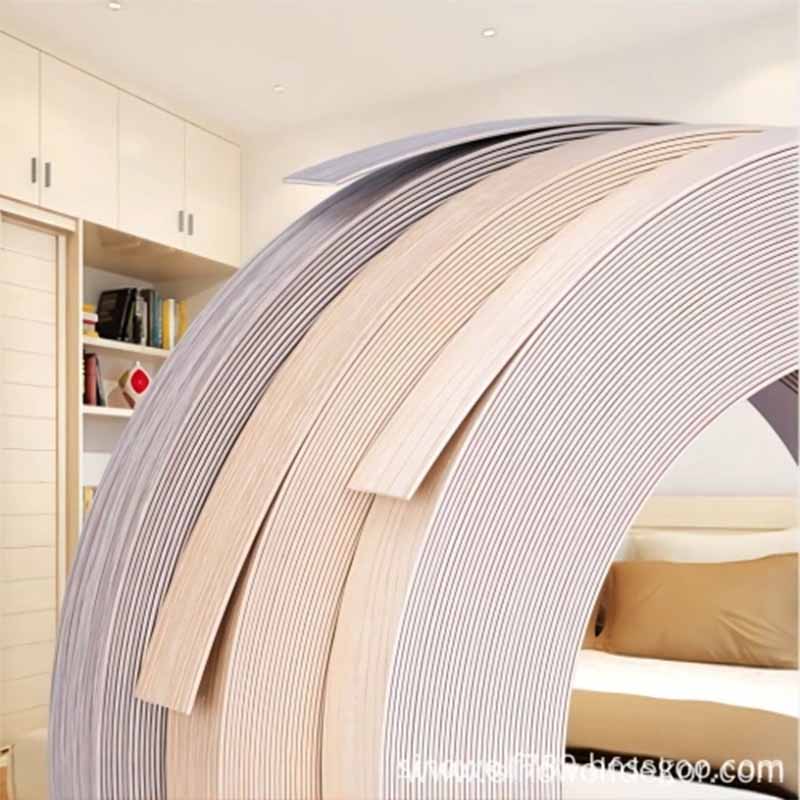

The origins of PVC edge banding can be traced back to the mid-20th century when the demand for cost-effective and aesthetically pleasing furniture solutions began to rise. As the furniture industry sought alternatives to solid wood edges, the development of synthetic materials gained traction. PVC, with its inherent properties of flexibility, durability, and cost-effectiveness, emerged as a promising candidate.

1970s-1980s: Rise in Popularity

The 1970s witnessed a significant surge in the adoption of PVC edge banding as manufacturers recognized its potential to address both functional and design-oriented requirements. During this period, advancements in manufacturing processes allowed for the production of thinner and more flexible PVC strips, enabling a more seamless and sophisticated finish to furniture edges.

Technological Advancements:

The 1990s marked a turning point for PVC edge banding with the integration of advanced technologies. This era saw an expansion in the range of available colors, patterns, and textures, providing designers with greater creative freedom.

Environmental Considerations:

In response to growing environmental concerns, the 21st century brought about a shift towards sustainable practices in the manufacturing industry. PVC edge banding manufacturers began exploring eco-friendly formulations, incorporating recycled materials, and developing processes that minimized environmental impact. This commitment to sustainability not only aligned with global trends but also positioned PVC edge banding as a responsible choice in furniture design.

Contemporary Innovations:

As of the present day, PVC edge banding continues to evolve with ongoing innovations. Advancements in 3D printing technology have allowed for the creation of hyper-realistic textures, enabling PVC edge banding to closely mimic the look and feel of natural materials like wood. Additionally, the development of antimicrobial PVC edge banding has addressed the demand for hygienic and easy-to-maintain furniture surfaces in various settings.

Conclusion:

The journey of PVC edge banding from its early days to its current state reflects a story of adaptability, innovation, and a commitment to meeting the ever-changing needs of the furniture industry. As technology, design trends, and environmental considerations continue to shape the landscape, PVC edge banding is poised to remain a crucial element in the creation of durable, aesthetically pleasing, and sustainable furniture designs for years to come.